Karfe weji

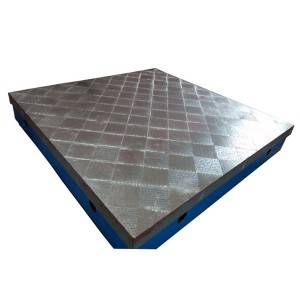

An fi amfani da weji na ƙarfe a farkon lokacin ginin wutar lantarki don daidaita daidaiton katako na ƙarfe ko don shigarwa da daidaita kayan aikin inji da kayan aikin injin.An fi amfani da ƙarfe na ƙarfe na ƙarfe don shigarwa da daidaita tsarin karfe, da shigarwa da daidaita kayan aiki;Halayen sune: m surface, high ainihin, babu burrs a kusa, mai kyau tauri, da kuma sauki don amfani

Bukatun fasaha don wedge Karfe: an ƙayyade daidaito bisa ga buƙatun, saboda kullun yana amfani da manyan bangarori na sama da ƙananan, don haka buƙatun ga bangarorin hudu ba su da girma, kuma rashin daidaituwa na shinge na karfe shine 6.4;Ƙaƙƙarfan saman saman da ƙananan ƙugiya shine 12.5, 6.4, 3.2, 0.8, da dai sauransu, idan daidaito ya fi girma, ƙayyadaddun da daidaituwa na shinge na karfe da aka sarrafa ta hanyar grinder bazai wuce 0.03mm ba.Za'a iya ƙayyade kauri na shinge na karfe bisa ga ainihin bukatun da kayan aiki da ƙayyadaddun kayan aiki;gangara na shingen karfe ya kamata ya zama 1 / 10-1 / 20, ƙwanƙarar ƙarfe na vibration ko madaidaicin kayan aikin gangaren shim) na iya zama 1/40.Lokacin amfani da tsinkar karfe, ya kamata a yi amfani da shi tare da shim ɗin lebur na ƙayyadaddun ƙayyadaddun.Ya kamata a yi amfani da tudun ƙarfe a cikin nau'i-nau'i.Ya kamata a yi amfani da gangaren guda ɗaya.

An tsara zane-zane na shinge na karfe bisa ga ainihin bukatun kayan aiki na kayan aiki, sa'an nan kuma ana sarrafa su bisa ga zane-zane.

Yadda ake amfani da weji na karfe

Sanya shim mai lebur akan harsashin siminti, sa'an nan kuma sanya shingen karfe biyu a kan lebur ɗin.Lokacin yin gyare-gyare, yi amfani da guduma don buga nau'i biyu na karfe, ana amfani da gangaren dutsen karfe don ɗagawa ko rage kayan aiki don cimma manufar daidaita matakin.Bayan an daidaita matakin, tabo weld ɗin ƙarfe na ƙarfe tare da tushe na kayan aiki don sa shim ya tsaya da ƙarfi.A ƙarshe, ana zuba shi da kankare don kiyaye kayan aiki a cikin kyakkyawan matakin yayin aiki, rage lalacewa da tsagewar inji, da rage farashin maye gurbin kayan aiki.